Efficiency and Safety with Versalift’s Load Moment Control (LMC) whilst Working at Height

In the world of working at height, the need for efficient and safe access at elevation is paramount. Access platforms equipped with Versalift’s Load Moment Control (LMC) technology have revolutionised the way we can carry out tasks at heights, ensuring both maximum outreach for the load and stability.

In this blog, we delve into the significance of LMC, exploring its ability to optimise the working envelope without compromising safety.

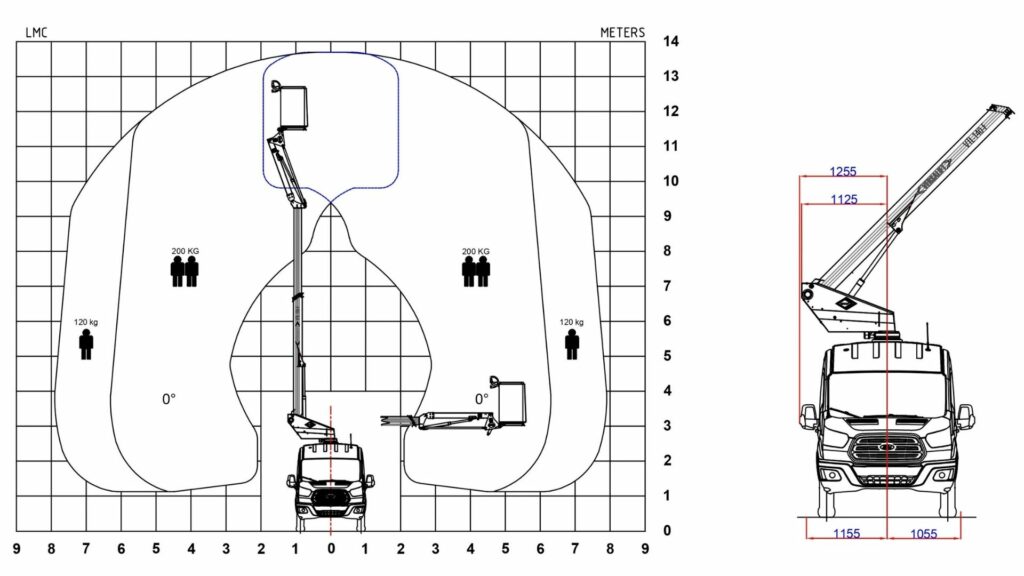

Versalift VTL 135 F E-Transit Access Platform EV Working Envelope

Understanding Versalift’s Load Moment Control (LMC):

Load Moment Control is a technology embedded into our access platforms to enhance safety by preventing overloading and optimising performance. This sophisticated system takes into account the weight in the basket, constantly calculating and adjusting the working parameters to provide maximum outreach for the load while ensuring stability.

No Compromise Working Envelope:

One of the key features of LMC is its commitment to maintaining a “no compromise” working envelope. This means that the technology is designed to offer the utmost flexibility and reach without jeopardising the safety of the operator or the access platform. A no-compromise working envelope implies that the aerial work platform can efficiently operate at its maximum working height and outreach while staying within the designated safety limits.

Maximum Working Height and Outreach:

LMC technology shines when it comes to defining the maximum working height and outreach based on an access platform’s capabilities within a specific working area. For instance, a Versalift VTL-135-F access platform offers an impressive maximum outreach of 8 metres and a maximum working height of 13.5 metres.

Benefits of Load Moment Control:

Enhanced Safety:

LMC technology plays a pivotal role in preventing overloading, reducing the risk of accidents and injuries associated with exceeding weight limits.

Maximised Efficiency:

The ability to work at maximum outreach for the load allows professionals to access difficult-to-reach areas, increasing overall productivity.

Reduced Downtime:

With LMC ensuring stability and preventing unsafe operations, the likelihood of equipment breakdowns and downtime is significantly reduced.

Operator Confidence:

A no-compromise working envelope instils confidence in operators, enabling them to focus on their tasks without concerns about equipment limitations.

Load Moment Control (LMC) is undeniably a game-changer in the realm of access platforms. By prioritising safety and optimising the working envelope, LMC technology empowers operators to tackle tasks with confidence, efficiency, and precision. As the industry continues to evolve, embracing innovations like LMC ensures that the future of working at heights is both secure and productive.