How Rental Businesses Reduce Downtime Through Proactive Service and Parts Support

Running an access platform rental fleet demands more than just having the right machines on the books.

Every hour a unit is off hire means lost revenue, disruption for the customer and pressure on the Rental Operations Lead who is responsible for keeping fleets working.

Downtime is the enemy — and proactive service and parts support are the most powerful tools to prevent it.

Why Downtime Hurts Rental Providers

Every rental business knows the pressure:

-

Customers expect machines on site, ready to work

-

Short lead times mean there’s little room for repair delays

-

Engineers are stretched across multiple depots and customers

-

Seasonal peaks create workshop bottlenecks

-

Call-outs can become costly and unpredictable

In an environment where availability drives profitability, even a single unplanned breakdown can disrupt scheduling, damage customer confidence and reduce utilisation rates.

The Shift From Reactive to Proactive Support

For many rental businesses, the solution lies in moving away from firefighting breakdowns and towards planned service programmes and reliable access to parts.

Scheduled Preventative Servicing

Routine servicing spreads workload evenly across the year and prevents surprise failures.

When platform inspections are planned ahead:

-

Parts can be ordered before a machine is due in

-

Engineers can batch similar service requirements

-

The fleet stays compliant with a LOLER

-

Workshop slots and field call-outs are more predictable

A proactive calendar helps a Rental Operations Lead stay one step ahead — rather than reacting to issues as they appear.

Condition-Based Maintenance and Early Warning Signs

Technicians across the UK are increasingly using:

-

Operation-time tracking

-

Wear-pattern monitoring

-

Common-failure statistics by model

By spotting early signs — hydraulic leaks, worn pads, boom chain tension changes, electrical sensors — repairs can be scheduled at a time that suits the hire schedule.

Stocking Critical Parts

Keeping a fleet-specific buffer of high-usage items ensures service teams never wait for staples like:

-

Filters and seals

-

Pins, bushes or wear pads

-

Safety systems components

-

Sensors, switches and batteries

This reduces workshop delays and allows fast turnaround between hires.

Why Reliable Parts Supply Matters for Rental Fleets

Even the best-organised workshop can’t prevent downtime if the right parts aren’t available when they’re needed.

OEM Parts Ensure Faster Fixes

OEM components are engineered for the platform — saving time during fitting and helping maintain reliability and resale value.

Fast Delivery Keeps Fleets Moving

When a platform is returned early with a fault or breaks down on hire, rapid access to parts can recover days of utilisation.

Rental operations require:

-

Next-day or same-day delivery

-

Real-time availability checks

-

Direct advice from OEM parts experts

Access To Technical Support

A parts order without the correct fitting knowledge creates delays.

Direct access to OEM technical assistance ensures fixes happen right the first time — without repeated call-outs.

The Role of a Dedicated OEM Service Team

Working directly with the manufacturer brings advantages rental companies rely on.

Field Service Engineers Across the UK

Nationwide coverage means:

-

Responders can reach the machine quickly

-

Faults are diagnosed accurately

-

Repairs are completed same-visit wherever possible

This is essential when customers are on site waiting to work.

Genuine Service Expertise with Model Familiarity

OEM technicians understand:

-

Platform configuration and hydraulics

-

Common problems by age and usage

-

Component inter-dependencies

-

The quickest fix that keeps the platform compliant

This knowledge saves time — and time is the Rental Operations Lead’s most valuable resource.

Support Across the Entire Platform Lifecycle

From early service milestones to mid-life overhauls and end-of-life replacement planning, a proactive programme ensures peak performance and predictable costs over multiple hire cycles.

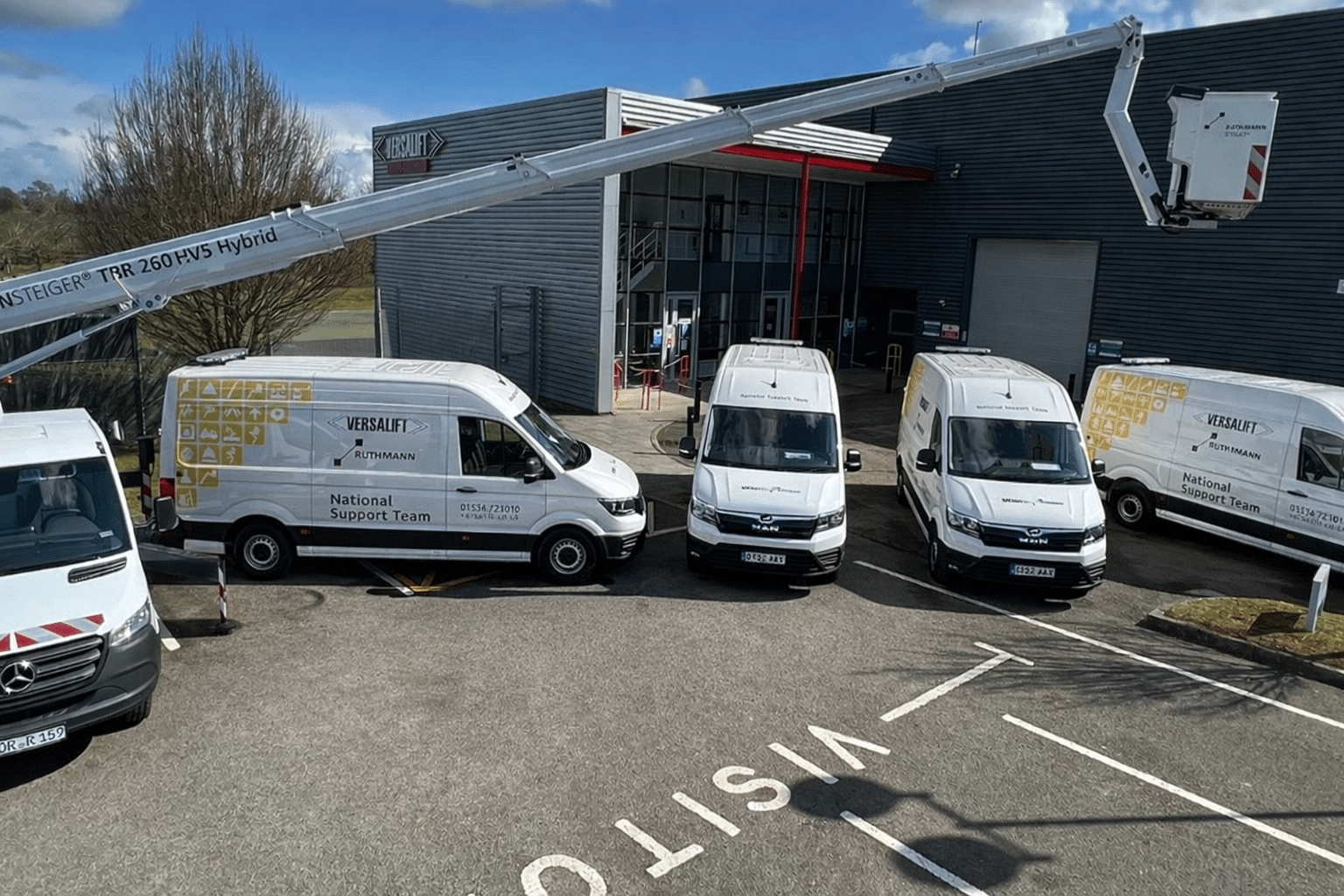

How Versalift Supports Rental Operators

Versalift provides nationwide support tailored to the pressures rental operations face:

- Scheduled preventative servicing

- LOLER inspection and compliance

- UK-wide mobile engineers

- OEM parts stocked and dispatched quickly

- Technical support from specialist engineers

- Workshop repairs, diagnostics and refurbishments

- Fleet age and utilisation planning

With the right parts and service structure, rental businesses can minimise downtime, maximise utilisation and support customers — even in peak demand.

Ready To Strengthen Your Fleet Performance?

Whether you’re managing a handful of platforms or a nationwide rental fleet, proactive support starts with a conversation.

Get in touch with Versalift UK’s Parts & Service Team to discuss scheduled maintenance, priority parts access and uptime planning for your fleet.

Follow us for our latest news, advice and products.